Dynamic. Different. Dedicated.

The specialist for flexible moldings and functional parts.

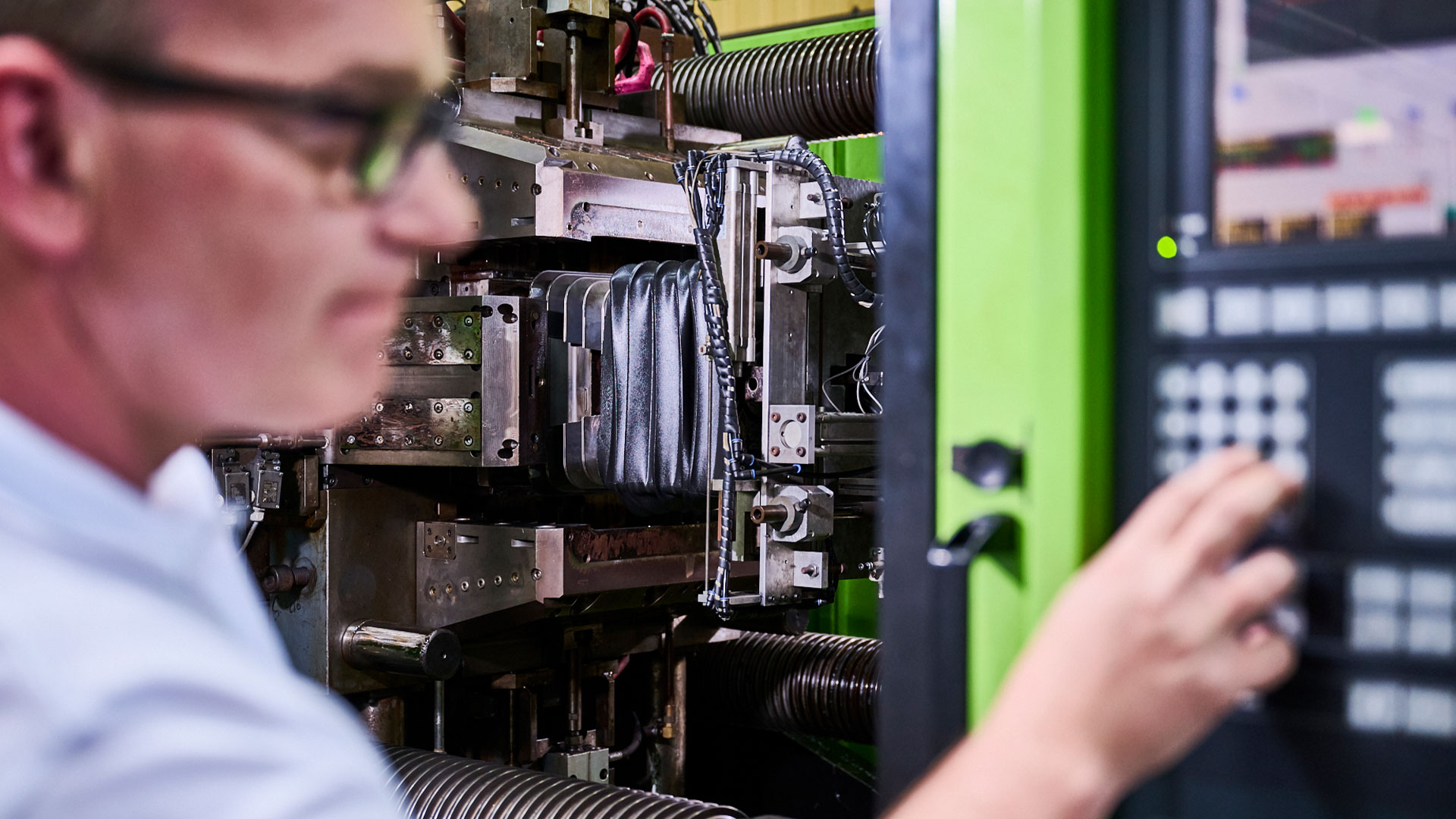

MöllerFlex GmbH is a proven specialist in the development and production of flexible moldings and functional parts made of various soft plastics, thermoplastics, and elastomers. We primarily supply the following customer target groups: manufacturers of white goods and trucks and tier 1 suppliers.

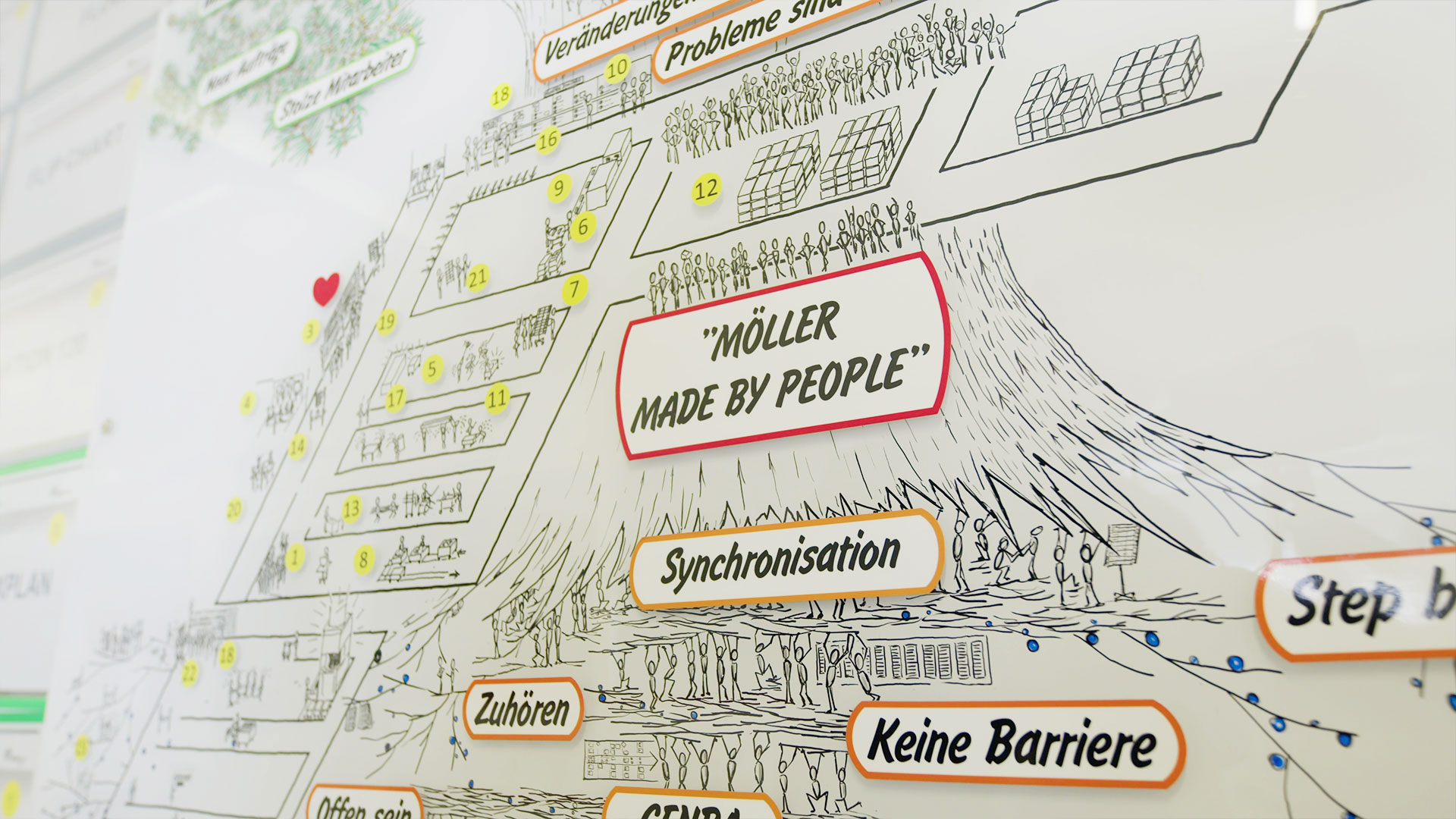

What we stand for.

Dynamic. Different. Dedicated.

As a result of the knowledge that we have acquired over many years and countless successful product developments, we have an extremely high level of solution expertise and an in-depth technical understanding of technologies, automation, and materials. The basis for our success is our corporate culture, where the focus is on our employees.

Products.

Dynamic. Different. Dedicated.

As specialists in flexible plastics, we are experts not only in vacuum cleaner bumpers, impellers, seals, and air ducts used in household appliances, but also bellows and gaiters, housings, covers, seals, handles, dampers, and parts for cockpits, car bodies, and engine compartments for the automotive sector — and our portfolio includes many other products and processes.

Process expertise.

Right from the start. The best solutions are created when we use our expertise early on as projects develop. This makes us a creative and innovative development partner for our customers in the best sense of the word. We develop customized and standard solutions in any quantity.

Careers at Möller.

Made by people since 1730.

What sets us apart from other employers is our special, grounded corporate culture that puts people first. Because we know that our success is based on the commitment of our employees.

MöllerGroup.

Stronger together.

Our strength lies in our diversity. MöllerGroup consists of four highly specialized, individual companies that together make an unbeatable team. This structure offers numerous advantages that set us apart from other companies.