Dynamic. Different. Dedicated.

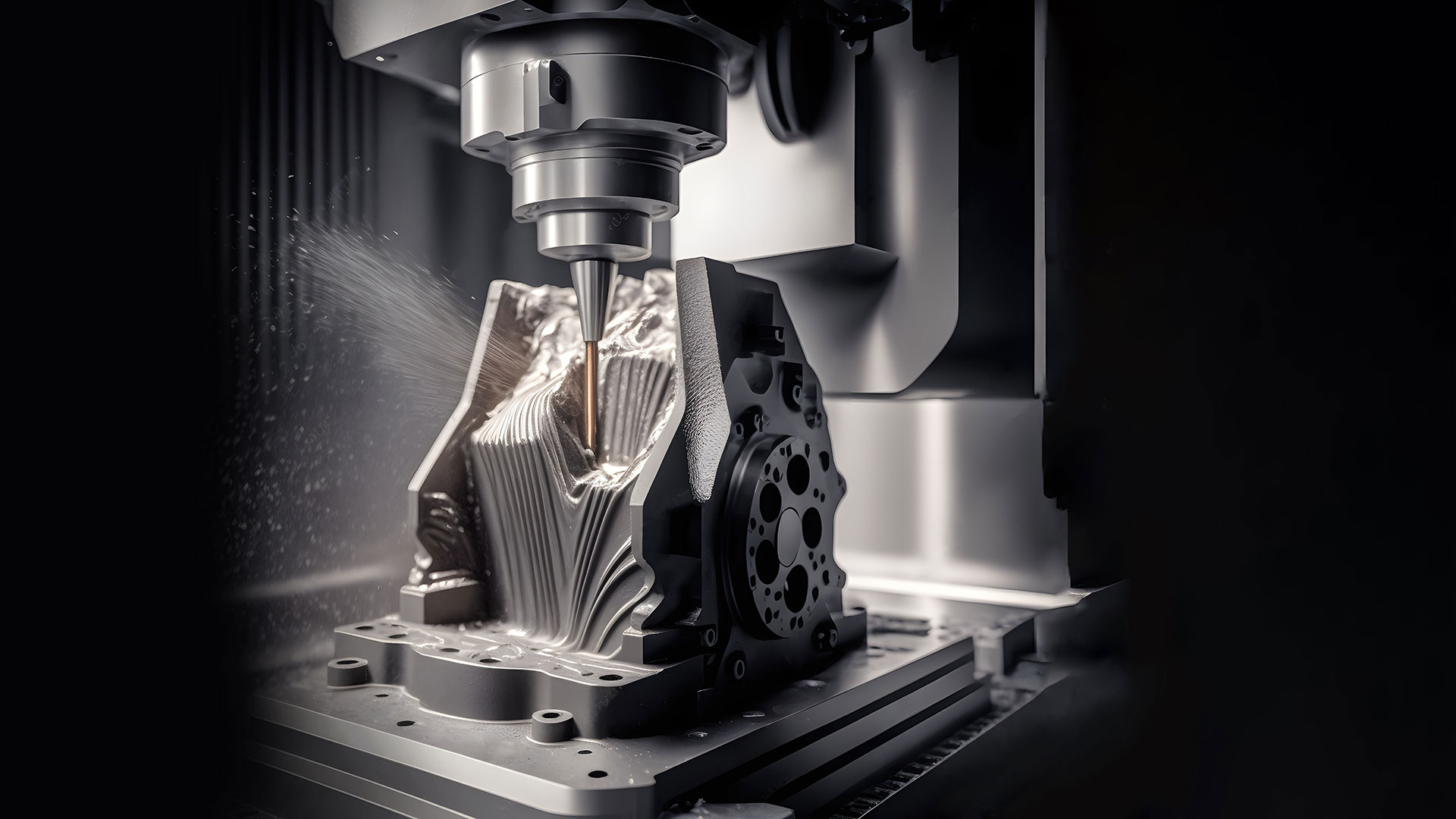

High-performance damper products made from plastic.

MöllerMiner GmbH is a joint venture between MöllerFlex GmbH and Miner Elastomer Products Corp. in Geneva, Illinois, USA. Using TecsPak® technology, we develop, manufacture, and distribute products such as high-performance plastic dampers.

What we stand for.

Dynamic. Different. Dedicated.

Thanks to the expertise we have acquired over many years, countless successful developments, as well as our deep technical understanding, we find the best and most efficient solutions for small-scale and large-scale production in the shortest possible time, creating unique and unrivaled products. The basis for our success is our corporate culture, where the focus is on our employees.

Products.

Here at MöllerMiner, our proven specialists create special products. Damping is what we do—no ifs, ands, or buts. That’s why we develop and manufacture efficient solutions that provide perfect damping for small-scale and large-scale production as well as just about every industry.

Services.

One thing’s for sure: the best solutions are created when we use our expertise early on as projects develop. This makes us a creative and innovative development partner for our customers in the best sense of the word. We develop customized and standard solutions in any quantity. We deliver proven quality every time.

Technologies.

Our damping technologies are small in size and big in performance. Using modified molecular chains, we perfect our customized designs to ensure optimum impact absorption. With the help of two innovative technologies, TecsPak® and TuLip®, we work with you to ensure optimum performance from your damping products to suit your needs.

CAREERS AT MÖLLER.

Made by people since 1730.

What sets us apart from other employers is our unique, down-to-earth corporate culture that puts our people at the heart of everything we do. Because we know that our success is rooted in the dedication of our employees.

THE MÖLLERGROUP

Stronger together.

Our strength lies in our diversity. MöllerGroup consists of four highly specialized individual companies that together make an unbeatable team. This structure offers numerous advantages that set us apart from other companies.

![[Translate to English:] MöllerGroup [Translate to English:] MöllerGroup](/fileadmin/moeller-werke/images/00-startseite/moellerwerke-startseite-gruppe-group.jpg)