Case study.

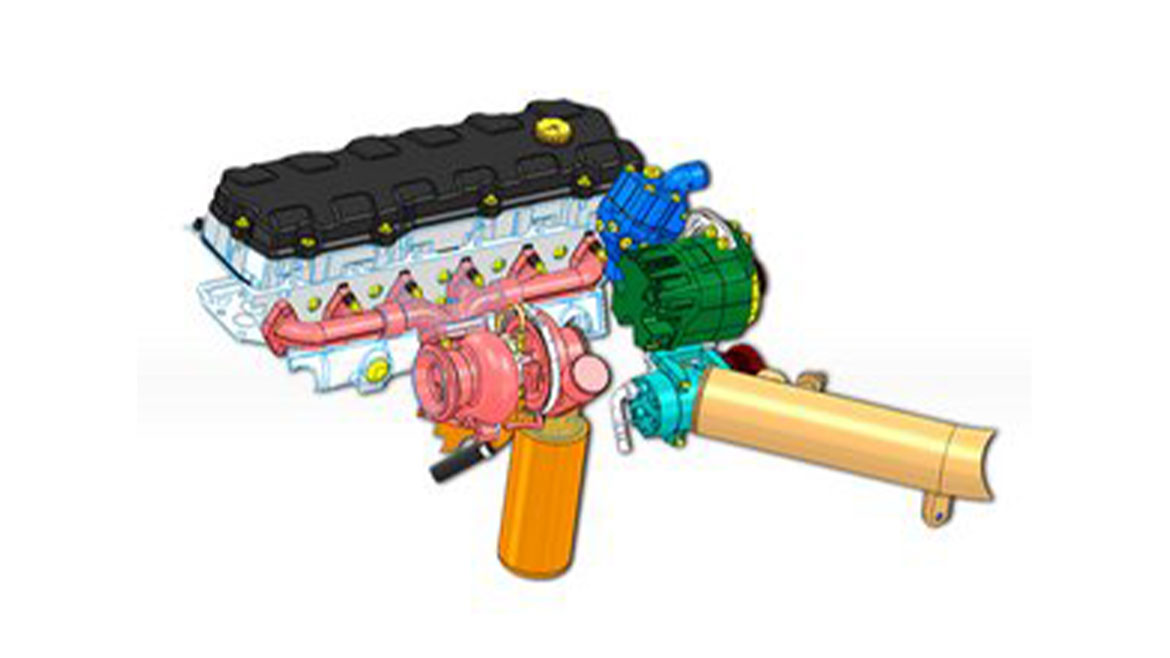

Air supply to a locomotive engine.

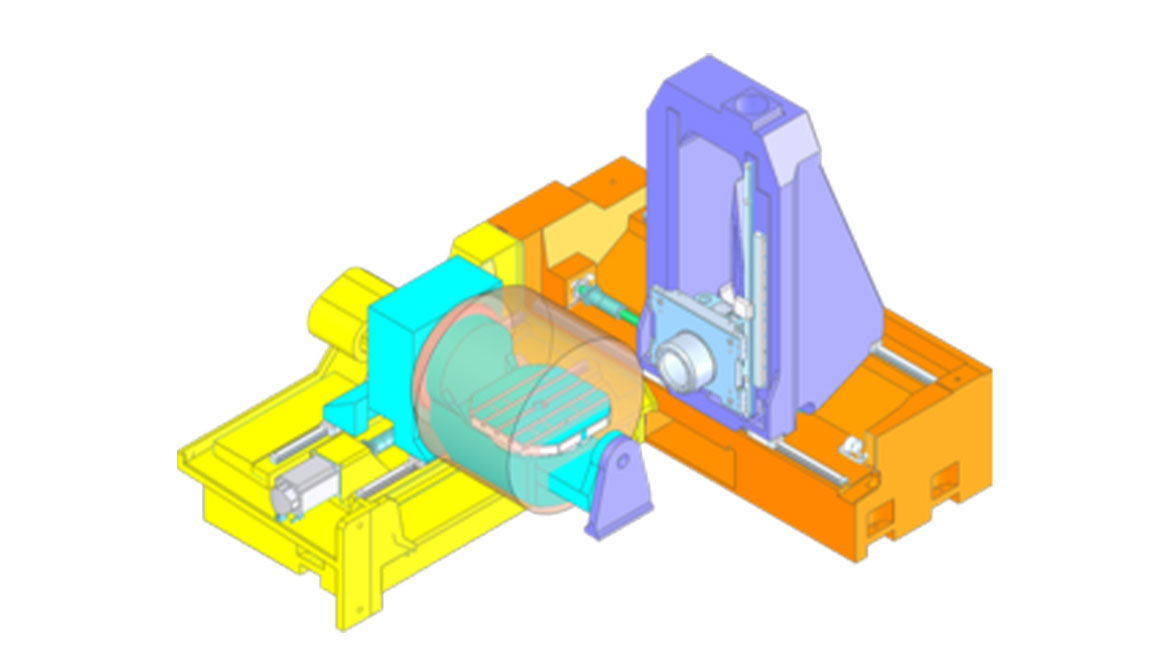

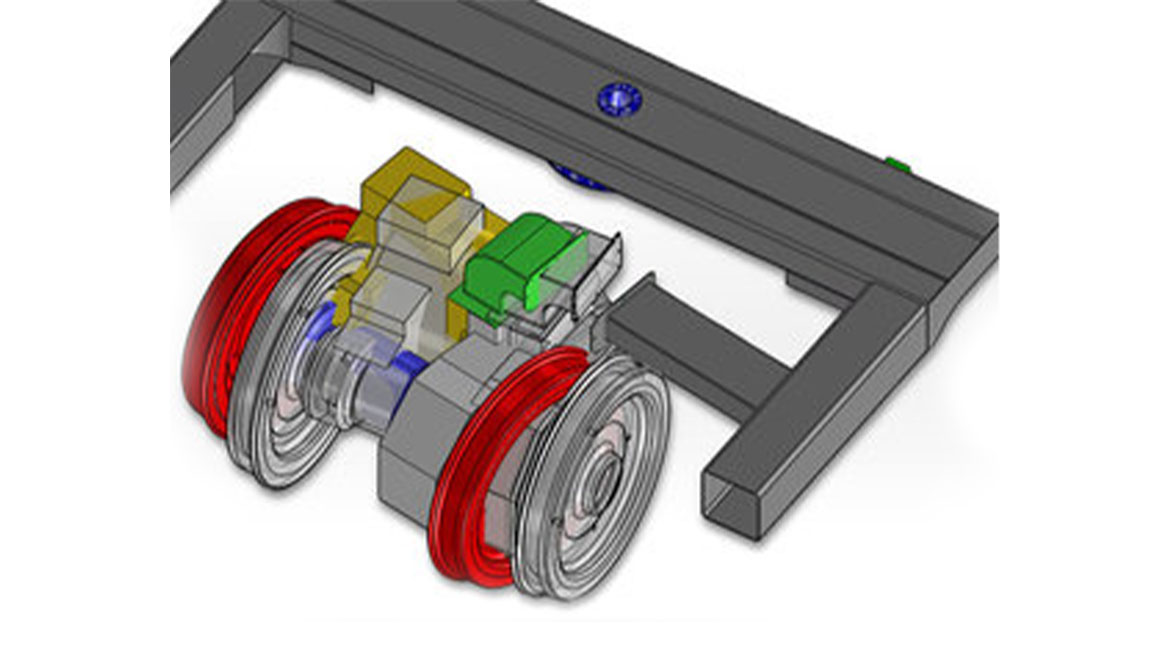

A manufacturer of locomotives provides the data model of a traction motor that is integrated in a railroad truck.

Requirements.

A manufacturer of locomotives provides the data model of a traction motor that is integrated in a railroad truck.

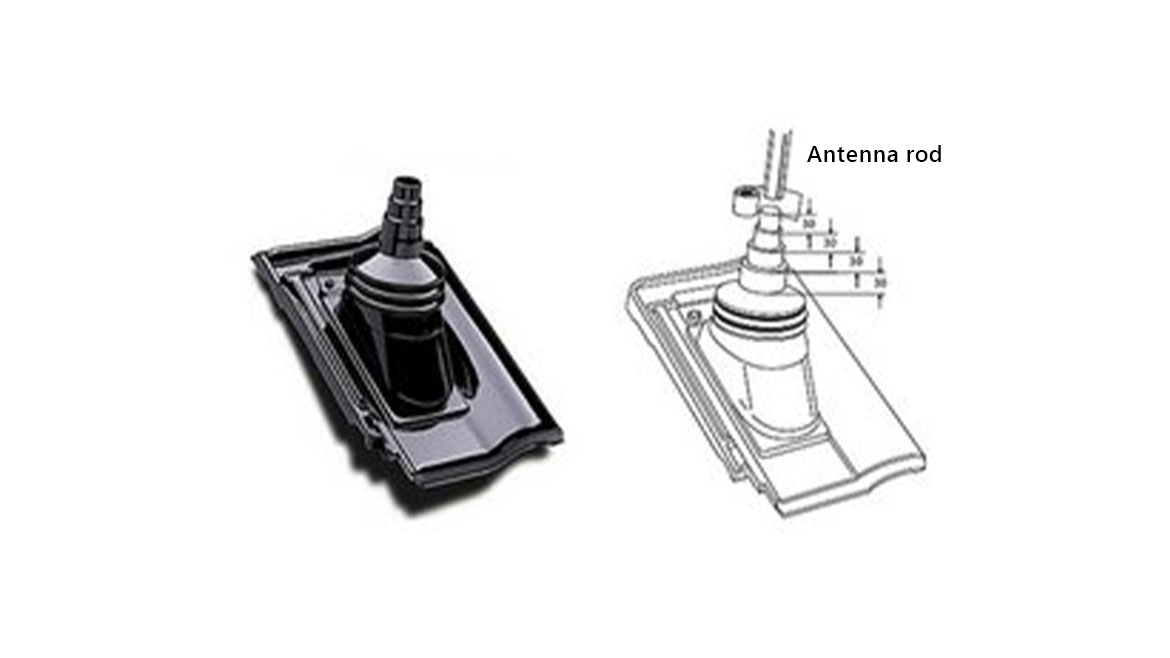

The task: continuous, reliable air supply to the traction motor. At the same time, the movement profiles occurring during driving and the pressure conditions in the air system must be taken into account.

Approach.

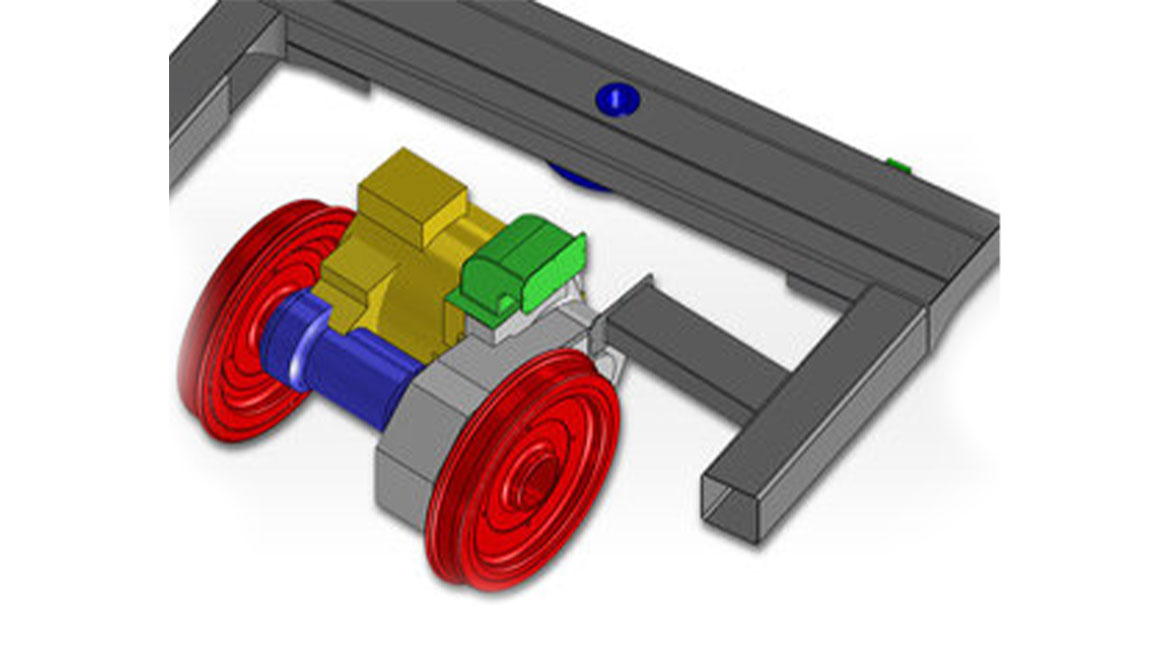

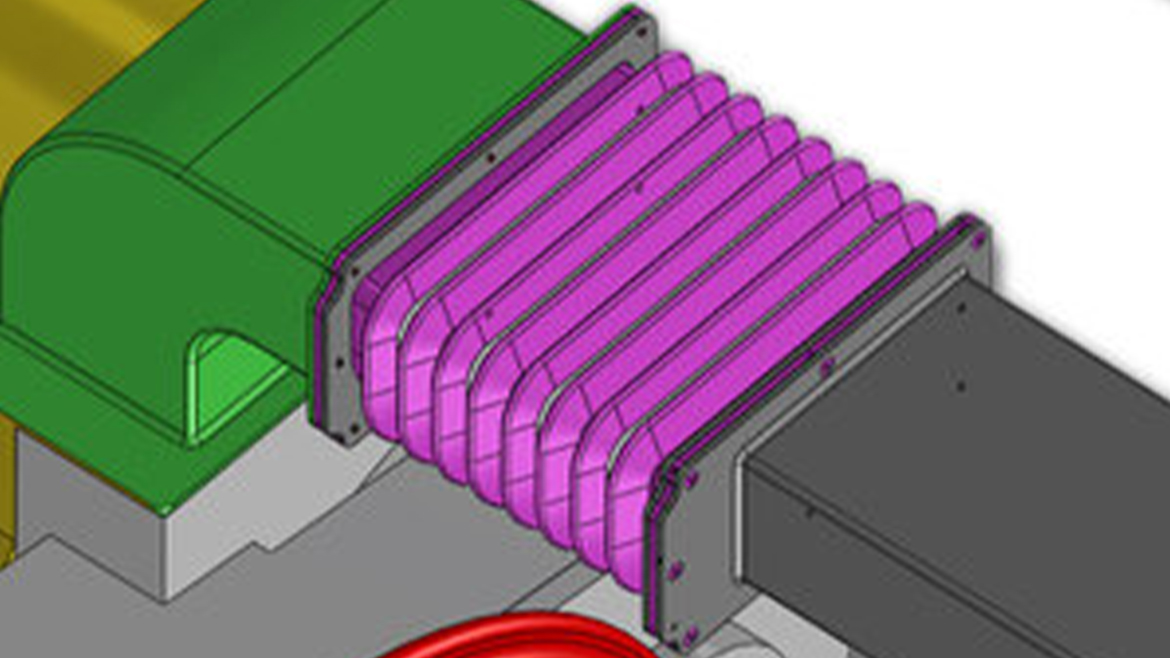

MöllerWerke uses motion studies and the customer’s specifications to determine the maximum deflection coordinates and designs a traction motor boot. This is graphically added to the customer’s file. The determined movements are verified on the company’s own test stand. The customer receives the concept with an offer.

Implementation.

The customer places the order. The drawing tool is used in a CNC-controlled drawing machine and is first produced as a prototype

Result.

Once the customer has tested and approved the prototype, production begins, followed by delivery of the series.