Case study.

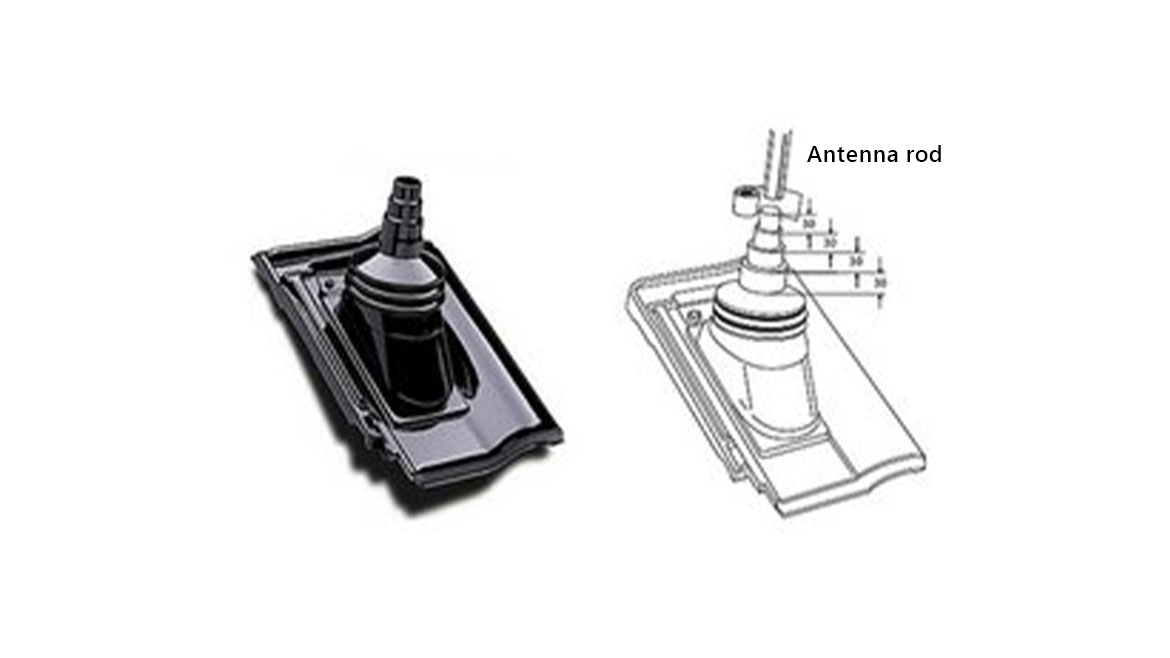

Cover for aerial outlet tiles.

Optimizing an existing cover solution for aerial outlet tiles.

Requirements.

The customer wants to optimize an existing cover solution for aerial outlet tiles. The existing solution is problematic when fixing the cover to the aerial outlet tile and cannot be effectively used because the flange connection is too thin. Deviation from the standard used is too great and optimization of the collar is desired.

Approach.

The customer wants to optimize an existing cover solution for aerial outlet tiles. The existing solution is problematic when fixing the cover to the aerial outlet tile and cannot be effectively used because the flange connection is too thin. Deviation from the standard used is too great and optimization of the collar is desired.

Implementation.

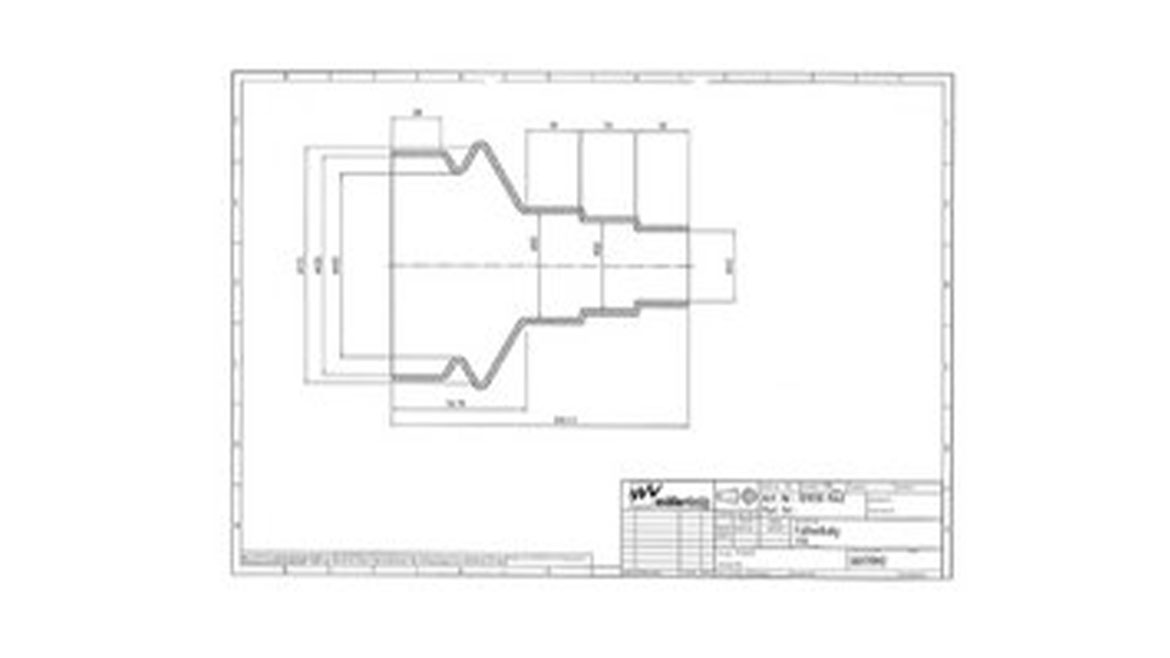

Based on years of experience in the development, engineering, and production of soft PVC bellows in the dipping process, a solution was developed. The cover was optimized in close cooperation with the customer. Based on the requirements, a new model that complies with the standard used was developed.

Result.

Modifications made to the individual segments of the bellows allowed for adjustments to the geometry. The item has a clear line, which is more suitable for the purpose. The modifications allowed for the standard used to be implemented. Based on 3D data analyses, the component in use was also optimized in terms of weight. The mass is reduced by about half, and the developed solution is therefore also optimized with regard to material consumption.