Case study.

Complete systems for machining centers.

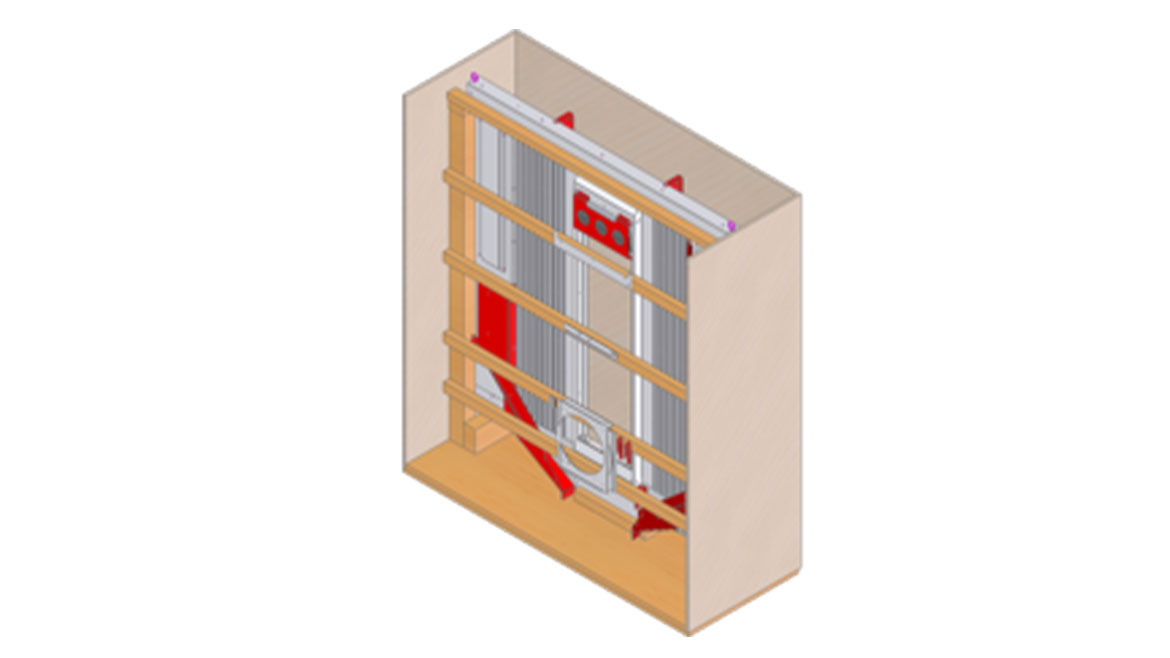

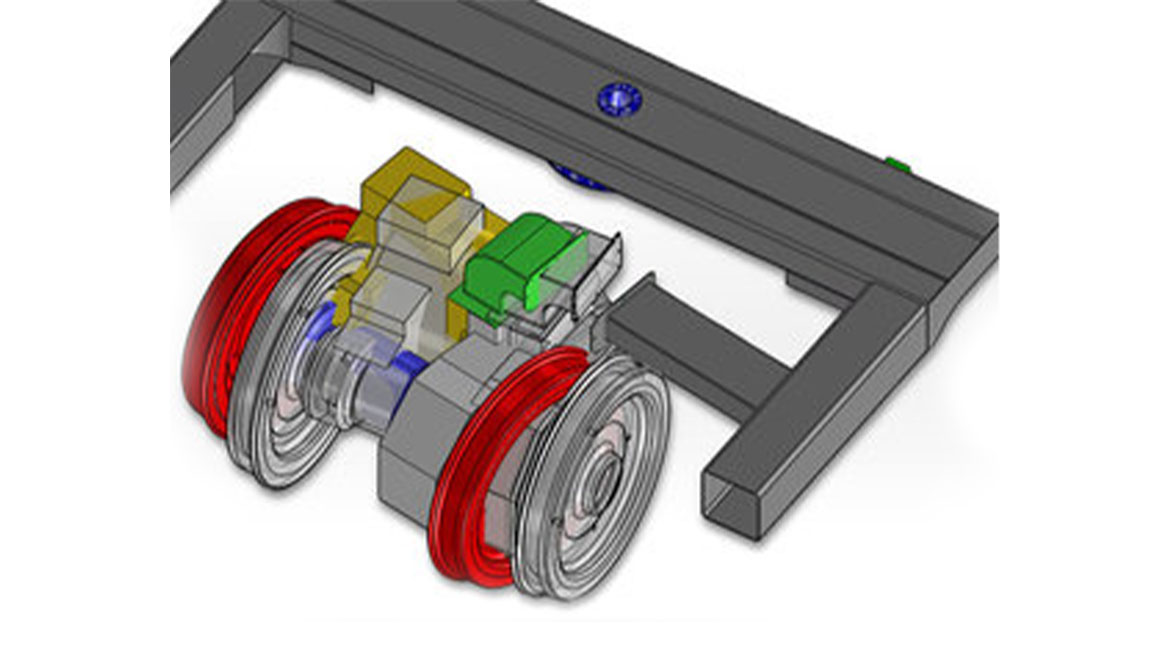

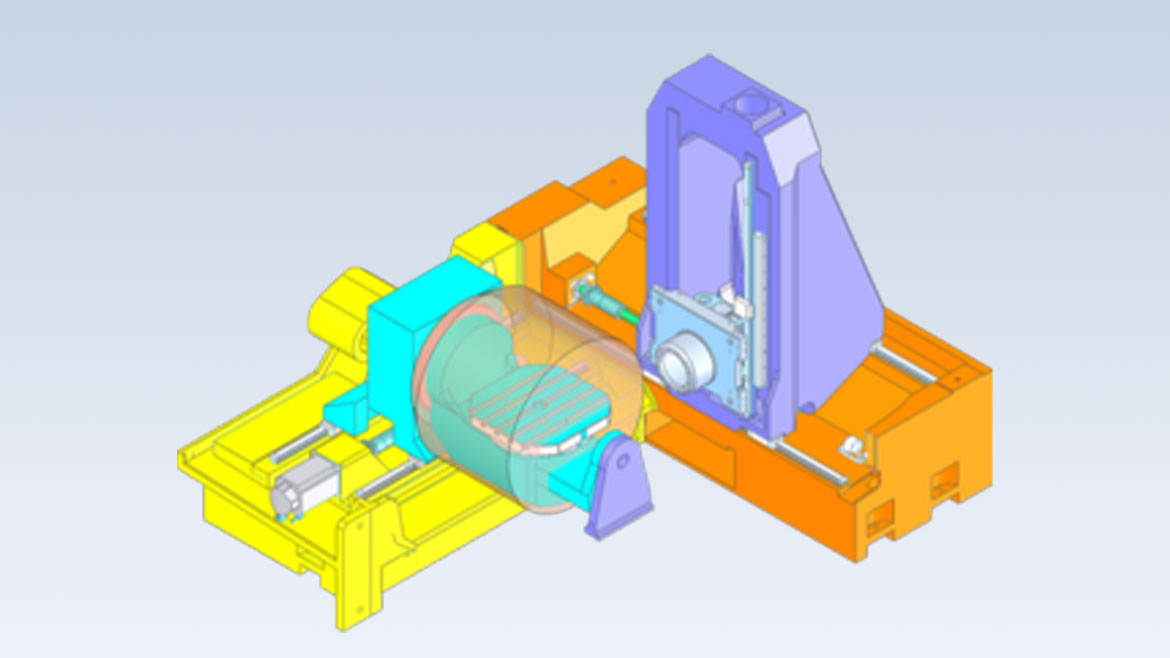

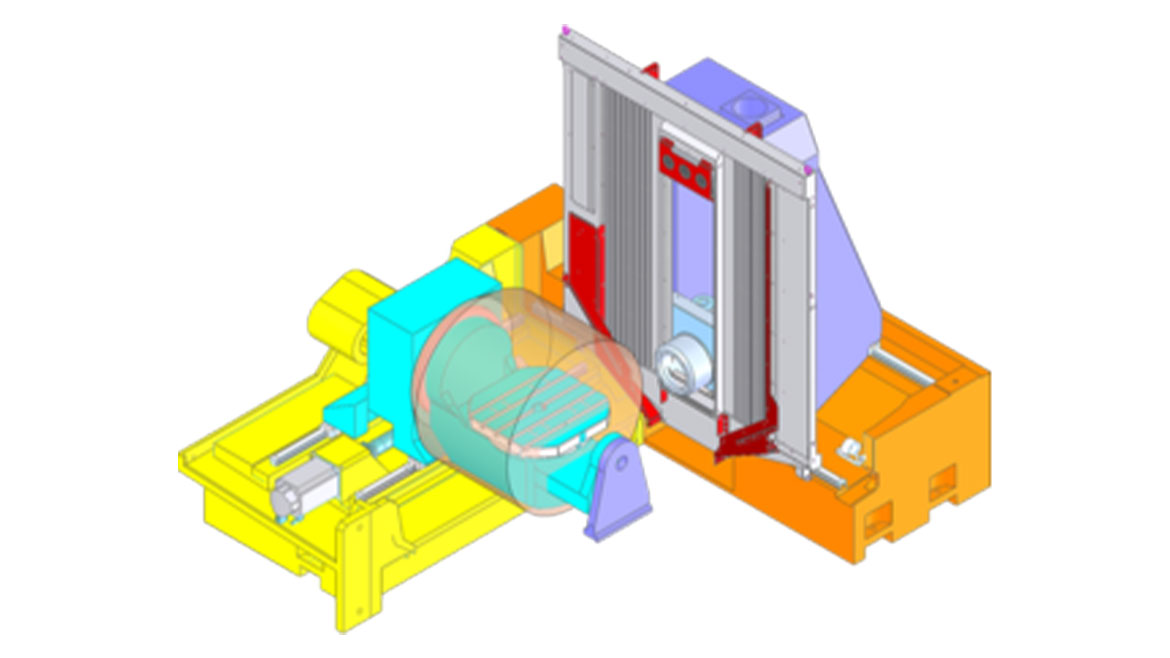

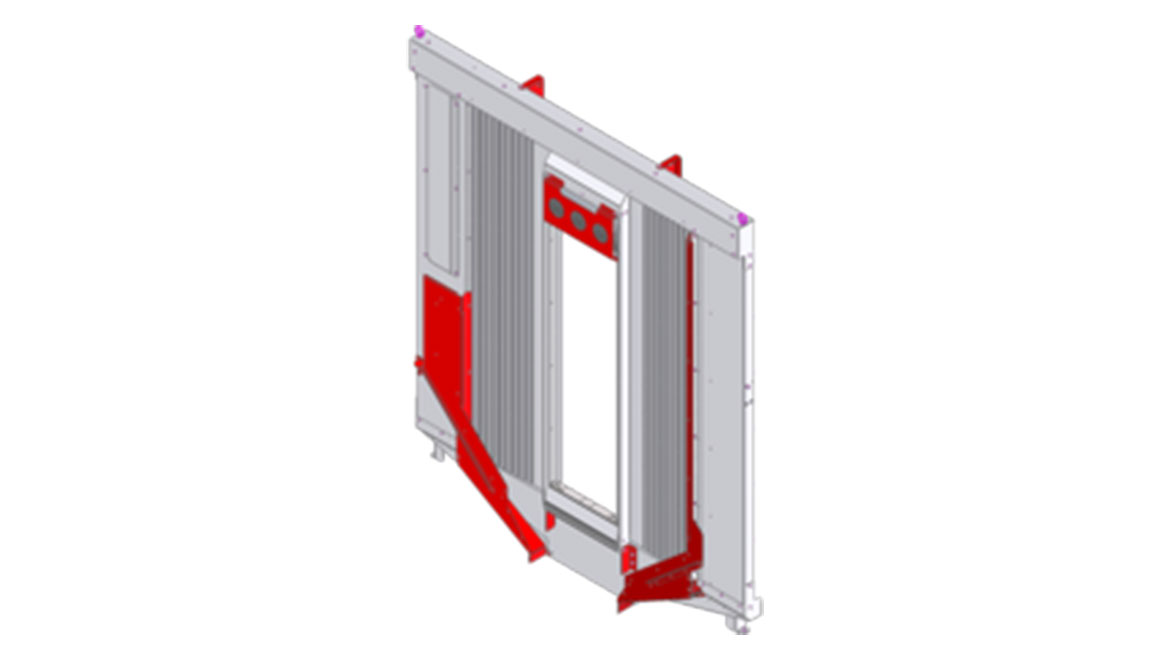

Development of a complete system including all covers, steel parts, and wipers.

Requirements.

A producer of tool machines requires a complete system for a newly developed machining center. The complete system should include all covers, steel parts, and wipers. Furthermore, all covers must be highly wear-resistant and chip resistant. A 3D data record is the basis of our work.

Approach.

MöllerWerke checks for feasibility and coordinates the details in close cooperation with the customer. From this, a quotation is created.

Implementation.

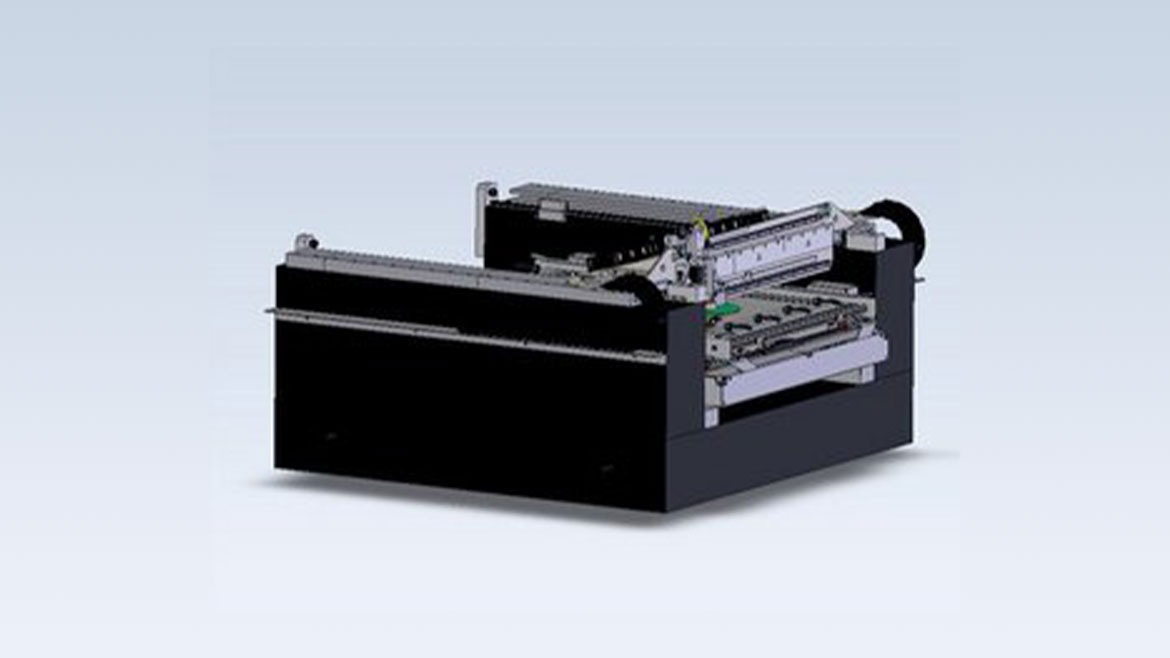

The customer orders an initial prototype. MöllerWerke produces the unit and delivers it to the customer completely pre-assembled.

Result.

Once the customer has thoroughly tested and approved the prototype, production begins, followed by delivery of the series.